Using the proper camera at the right location makes a lot of difference. If you are a factory owner constructing your factory’s video surveillance setup, you can use a variety of security cameras. Although omnidirectional video cameras are growing more common, they are still largely utilized.

They can record more specific data on an object, such as its size, shape, and location, which is crucial for handling and other tasks in industrial settings. For automated image generation and analysis, omnidirectional 3D vision systems are among the best industrial cameras.

The manufacturing and industrial sectors of the economy have made extensive use of technology. This article discusses omnidirectional 3D vision systems on factory floors, some advantages, and how to pick the best model for a certain task.

This article will discuss why we should use omnidirectional 3D vision systems for the factory floor.

What Omnidirectional 3D Vision Systems?

An omnidirectional 3D Vision system is commonly referred to as a 360-degree camera that records video in a nearly full sphere around the camera.

An omnidirectional camera observes and records everything in its field of view at the same time. This allows you to record a wide visual field with a single camera. There is no actual rotation or movement; the entire environment around the camera is taken all at once and then digitally shrunk.

That footage can then be viewed with VR goggles, with the view updating as the user turns their head, or on a regular computer screen, with the viewer pan and tilting inside the recorded environment using their mouse.

The Benefits of deploying Omnidirectional 3D vision systems on the Factory Floor

Multiple cameras are used in 3D machine vision systems to view the surroundings, location, and orientation of the target objects. The devices may carry out numerous tasks thanks to their numerous cameras or laser displacement sensors.

The following advantages are associated with omnidirectional 3D vision system functions:

Higher Compliance

Omnidirectional 3D vision systems facilitate process evaluation and problem tracing, which are crucial for compliance. Consider the scenario where a product problem is discovered. The process can then be examined using photos taken during production to identify the issue’s root cause and determine the best course of action.

Increasing Productivity

Robotics and machine vision technology combined allow businesses to operate for longer hours, which boosts productivity and increases income. In addition, making enough parts eliminates the need to outsource production, saving the company money and improving product quality.

Labor-saving

Omnidirectional 3D vision systems used for factory floor surveillance save much manual labor as it saves human labor from an undesirable working environment like work overload, allowing the workers to focus on other cutting-edge tasks that are advantageous to the company. Additionally, the cameras are smaller, which saves space, which is crucial in industrial environments.

Waste minimization

Omnidirectional 3D vision systems allow continuous process inspection to assure correctness on a factory floor or in an industrial setting. For instance, employing technologies for examining fan shafts makes it possible to quickly identify parts that would fit an engine with extreme precision.

Higher Efficiency

By reducing costs and boosting product quality, omnidirectional 3D vision systems on the production floor increase process efficiency. Automating repetitive tasks can save labor costs, which is necessary for lowering overall costs and increasing profit margins.

Leveraging omnidirectional 3D vision systems supports automated monitoring of processes like mechanical punch presses, proactively reducing operational defects and errors, and enhancing product quality. Higher product quality reduces the likelihood of product recalls by ensuring that components, such as optical gauging, meet the appropriate requirements.

Why are Omnidirectional 3D vision systems worth the factory floor?

In a physical security situation, Omnidirectional 3D vision systems have numerous advantages. It is easier to cover a place and prevent surveillance blind spots when you have a camera that records all perspectives.

Omnidirectional 3D vision systems are user-friendly for both technical and non-technical personnel to utilize since they feature many viewing modes. Set up tile view as a basic way for non-technical folks to explore the region, and then switch to comprehensive view to look around more extensively.

Finally, Omnidirectional 3D vision systems are one of the most efficient and effective ways to improve visibility in your area. They will not meet all of your demands, but they are a powerful and adaptable tool that practically every company may employ to improve safety.

How to Choose the Right omnidirectional 3D vision systems

When acquiring omnidirectional 3D vision systems, selecting the right camera for the task is critical to get the best results. The omnidirectional 3D vision systems best suited for various industrial settings are detailed by Dream Vu and a selection of cameras.

Choosing the appropriate camera, lens, controller, and display for inspection purposes in various manufacturing scenarios where human interference is not possible is crucial. The sensor size must always coincide with the lens picture cycle for optimal results. Machine vision cameras must match the lens to the pixel size and resolution of the sensor to ensure compatibility.

PAL

With a good depth range of 10 meters and no minimum depth, PAL offers a 360° horizontal field of view and a 110° vertical field at up to 9 megapixels. With the ability to create a comprehensive 3D occupancy map from each frame, PAL is the perfect sensor for autonomous mobile robots (AMR) navigation systems. By giving ODOA and SLAM a thorough grasp of the surrounding area, PAL enables AMRs to localize and travel along the most direct routes.

PAL Mini

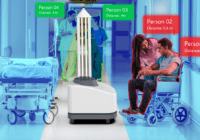

The PAL Mini is the most portable omnidirectional 3D vision system, with a good depth range of 5 meters and a 360° horizontal field of view with an 80° vertical field of view at up to 4 megapixels. PAL Mini is ideal for navigation systems in smaller AMRs and domestic robots because of its compact form. In applications where increasing the cleaning area is crucial, such as people identification in disinfection robots or wall, cliff, and stair tracking in commercial cleaning robots, PAL Mini can also be used as an additional sensor.

Conclusion

Omnidirectional cameras may soon replace limited field-of-view and PTZ cameras in a lot of warehouses, manufacturing floors, and storage facilities due to greater resolutions and more efficient technologies.

DreamVu is leading the development of the next generation of visual intelligence and revolutionizing how machines and people see the environment with camera-based systems that use unique optics and imaging software to lower system costs and give an unmatched field of vision.